Add to Cart

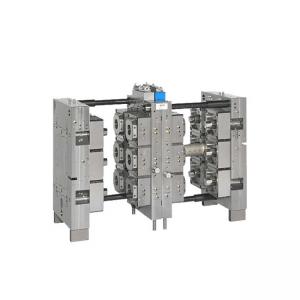

PC Components CNC Custom Small injection molding Precision Elements

Quick detail

Mould Material:P20/718/738/NAK80/S136/H13/S50C/738H/1.2344/1.2738

Shaping Mode:Plastic Injection Mould

Type of Plastic Material :ABS, ABS+PC, PP, PS, POM, PVC, TPE, TPU, PA6,PA6.6+30GF,PPUS,PPS ,GPPS,etc.

Slider:Outer, Inner Slider, Lifter

Parameter

| Cavity | Multi Cavity/single Cavity | Application | Machinery/medical/automotive/electronic |

|---|---|---|---|

| Process | Injection Molding Process | Drawing Format | Dwg .step .igs |

| Mould Life | 300,000-500,000 Shots | Runner | Hot Runner/cold Runner |

Product show

Our service

1. R&D: We support customer R&D. Make the files or improve the design if you needed.

2. Quotation Making: Mould quotation will be finished in 1 day according to information we get.

3. Negotiation: The quality, price, material, deliver time, payment item and so on.

4. Mould Design:3-5days for mould and product 3D/2D drawing design.

5. Mould: According to customers' request to build the mould before make the mould. We send mould design to customer approval first.

6. Mould Testing: When moulds are finished, we test the moulds to check it satisfied consumers' needs. And we will send samples for consumers' reference.

7.Sample shoot:If the first sample come out is not satisfied customer. We modify the mould and until meet customers' satisfaction.

8. Delivery: Delivery goods by sea or by air, according customers requirement.

About us

Precision Mold Components could be applied to many industries. The company has high-end imported equipment and skilled employees to ensure the processing size and product quality.As a professional mold manufacturer services provider, GODE is able to plan undertake the entire mold manufacturing process for new products launched by the customers and to assist them in moving their products from their conceptual design to mass production efficiently and economically,thereby allowing customers to focus on other aspect of the production and marketing of their products and enabling them to exploit early market opportunities for their products.

We provide value-engineering and manufacturing excellence in plastic injection molding to our customers all over the world. From a single part, to a complex assembly, our engineering services will meet, or exceed your project specifications and requirements. We utilize the most advanced technology manufacturing systems and processes in the industry to deliver quality-critical parts on time, every time at competitive prices.

FAQ

Q1. Are you factory or trading company?

Q5.How could I pay them?

T/T,L/C,Western Union ,Credit Card,PayPal are acceptable.